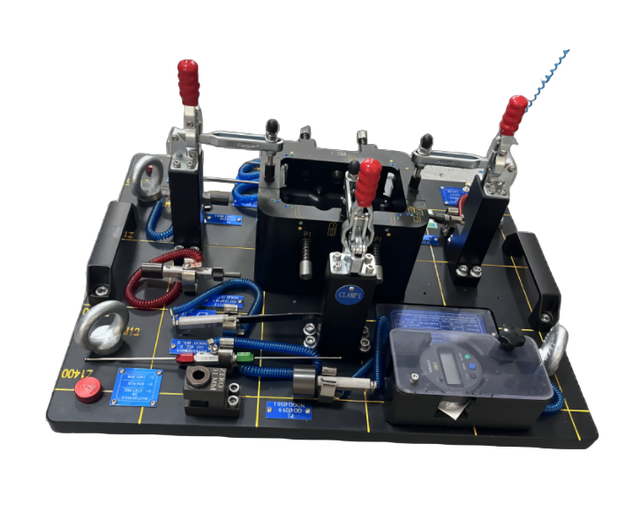

Checking Fixture

High Quality Checking Fixture Supplier-HT Tool&Die

Going beyond just producing stamping die and molds, HT Tool&Die can build a checking fixture or gauges to check metal stamp parts for our stamping processing. Each inspection gauge tooling & check fixtures are CMM and 3D scanner checked and verified to meet or exceed our customer‘s desired specifications and tolerances.

Professional Team: We build a very experienced engineering and skilled toolmakers team to ensure every part of the checking fixture is delivered to our customers completely.

Project management: We focus on strong project management to deliver quality gauges to our customers on time. Our management team is closely involved and directly worked from RFQ to PPAP stage.

Customized service: We will communicate well with each of our clients and learn what they need to make a customized solution for them independently.

Quick Response: No matter when you send us an inquiry or complaint, we can immediately respond as per the customer's request.

Do not allow children without adult supervision to use this product alone, children should not be left alone with product accessories, risk of choking.

Product Introduction

Checking fixture they’re used for checking—quality assurance and subsequent approval or rejection of already created components based on dimensional accuracy.And they certify that the product complies with all the necessary safety criteria and specifications.HT Tool checking fixture has high measurement accuracy without deformation, low maintenance cost and good convenience.Let's see how checking fixtures typically work.

Applications in Manufacturing:

- Automotive Parts Assembly:

Checking fixtures are widely used in the automotive industry or other industries to verify dimensions of components such as chassis elements, and interior fittings. They ensure that parts fit together correctly during assembly and meet stringent performance standards.

- Mass Production Environments:

If there are large quantities of identical or similar parts are produced, checking fixtures provides a cost-effective solution for ensuring uniformity and precision. This is crucial for meeting production targets without compromising on quality.

- Replacement of Specialized Measuring Tools:

Checking fixtures serves as a versatile alternative to specialized measuring tools like plug gauges and OD gauges. They offer simplicity in operation while still delivering accurate measurements, making them suitable for a wide range of manufacturing applications in automotive,aerospace,electronics and so on...

Benefits of Using Checking fixtures:

Cost Savings: Checking fixtures are generally more affordable than specialized measuring instruments, reducing capital investment in inspection equipment. Ease of Use: They are designed to be user-friendly, requiring minimal training for operators to perform inspections effectively. Reliability: Checking fixtures or gauges provides consistent and repeatable measurements, ensuring reliability in quality control processes. Scalability: Suitable for both small-scale and large-scale production environments, gauges adapt to varying production volumes and requirements.

Operation sequence of checking fixture

The below steps brifely describe a systematic approach to ensuring the quality and dimensional accuracy of manufactured parts using checking fixtures. Each step is crucial for maintaining quality standards and ensuring that parts meet customer requirements and specifications.

- Visual inspection this step is to check the outside of the checking fixture if there are any parts sharp edges, cracks, and burrs.

- Check size of holes:Using GO and NOGO pins to check the size of holes.

- Making Parts Good to Touch:Datum pins, net-pads, and magnets are used to ensure the part is correctly positioned and held securely in place within the checking fixture. This step ensures accurate and repeatable measurements.

- Adjusting part:Adjusting the part keep it well contact nets and loacate it with X/Y1/Z1 and Y2/Z2.

- Closing clamps: Close clamp Z1,Z2,Z3.

- Hole Position Checking:Using the P1 pins to check the hole position.

- Checking trim&surfaces:Using the feeler and trim gauge to check the trim and surface as the color points.

- Visual Edge Detection:Visually detect the edge of the material, it is qualified within +/-1.5 lines, and vice versa.

- Recording results:Recording results on the inspection sheet.This documentation is essential for quality control and traceability.

- Unclamping and removing part.Once inspection is complete and results are recorded, the clamps are released, and the part is removed from the checking fixture. This completes the inspection process for that particular part.

Remark: The checking fixture/gauges must be under a dustless environment with stable temperature and humidity when they are used to examine the product.For each set of checking fixtures,HT tool will send a manual instruction along with the shipment.

Checking fixtures plays an invaluable role in manufacturing industries like metal stamping or plastic injection, helping ensure products comply with desired specifications and standards. They have the following advantages:

- It reduces or sometimes eliminates the efforts of marking, measuring, and setting a workpiece on a machine, increasing the efficiency of production.

- Increases machining accuracy and ensure interchangeability.

- Increases productivity due to increase of seeds, feeds, and depth of cut, because jigs and fixtures provide high clamping rigidity.

- Increases productivity due to the possibility of machining two or more workpieces simultaneously or the number of cutting tools.

- Saves manpower by reducing manual handling operations.

- It’s simple to operate, Semi-skilled labor is sufficient.

- Increases versatility of machine tools.

- The workpiece and tool are relatively located at their exact positions before the operation automatically within negligible time. So it reduces product cycle time.

- Variability of dimension in mass production is very low so manufacturing processes supported by the use of jigs and fixtures maintain a consistent quality.

- It reduces the production cycle time so increases production capacity.

- Working with more than one tool on the same workpiece is possible.

- There is no extra need to examine the size of produce provided that the quality of employed jigs and fixtures is ensured, so this saves the time of quality checking.

Types of Checking Fixtures

- The larger metal parts are assembled by using the assembly fixtures.

- The adjustable fixtures can be used in the lathe where the different cutting tools could able to accommodate one setup.

- The grinding fixtures it give the accuracy for grinding parts like the connecting,rods, gears ,and fixtures.

- The welding fixtures that are used for holding up the parts that are required for shaping and it is used from smaller parts to the larger parts.

Designing and creating a checking fixture are crucial steps towards assuring precision in manufacturing processes, with creating one requiring careful planning, attention to detail and an in-depth knowledge of engineering principles. Here are some steps that may assist you through this process.

- First of all, information gathering must include dimensions, tolerances, and any special requirements or features which require inspection.

- Once a 3D CAD model of your part has been constructed using special software, use this model as the basis for designing its checking fixture. Focusing on aligning reference points and making sure access is available for measuring instruments is vitally important to its design success.

- After the CAD model is completed, start designing your fixture using appropriate materials like aluminum or steel. Keep stability, rigidity and ease of assembly top of mind at this stage of design. Fixtures should contain features to accurately position parts for measurement. Use datum references from engineering drawings to precisely pinpoint these locations.

- Consider including various gauges or sensors in your checking fixture design to achieve accurate measurements, from simple go/no-go gauges to more complex electronic probes or vision systems.

- Before finalizing your design, perform virtual simulations if possible to detect possible interferences or clashes with other components during operation and ensure functionality and reduce costly rework later on. Doing this helps guarantee efficiency while helping prevent costly reworks later.

- Once the design is approved, digitally verify it thoroughly before moving forward with fabrication. CNC Machining techniques like milling drilling turning can be utilized alongside traditional hand tools like saw files drills to cut shapes and assemble individual components according to client-provided specifications for final assembled products.

Common Materials Used for Checking Fixtures

Selecting materials suitable for designing and creating checking fixtures is of utmost importance in designing or building them successfully. The material should possess qualities like durability, accuracy, and stability – here are some materials frequently used:

- Aluminum.

- Steel.

- Composite Materials.

- Plastic 5. Epoxy Resins.

Quality Control and Maintenance of Checking Fixtures

- Quality control requires periodic tests of any checking fixture to make sure they’re functioning optimally, such as verifying measurements against known standards, conducting functional tests and inspecting for any wear or damage. This could involve checking measurements against standards set out for them as well as conducting functional tests or inspecting for signs of wear or damage.

- Maintenance plays an essential part in prolonging the lifespan of checking fixtures. Regular cleaning should remove debris or contaminants that might impact its performance; additionally, lubricating moving parts helps minimize friction and wear-and-tear.

- Regular calibration is also key for maintaining accurate measurements, so checking fixtures should be calibrated at set intervals using traceable reference standards to ensure they continue providing precise readings.

Our end-customer

Our Certificate:We have passed ISO9001:2015

Our Equipment

FAQ

Q: What is the checking fixture concept?

Q: What are the components of a fixture?

Q: What is a checking fixture design?

Q: What is the difference between a test jig and a fixture?

Q: How do checking fixtures work?

Q: What is the inspection checklist of a checking fixture?

Q: What is the difference between a gauge and a checking fixture?

Q: What are the important elements of inspection fixtures?

Q: What Are The Apply-Type Checking Fixtures?

Q: What Is Progressive Inspection Metal Match (PIMM) Fixtures?

Q: How to Coordinate Metal Matching Inspection Fixtures?

Q: What are fixtures in the automotive industry?